TrackIt

Track, Monitor, and Manage Your Fleet in Real Time

Save 20 Minutes Per Driver Each Day and Eliminate Paper Timesheets

Monitor Vehicle and Driver Performance in One Place

Keep Trucks Productive and Drivers Safe with Proactive Vehicle Maintenance Scheduling

Everything You Need For Fleet Performance

Keep drivers and dispatchers in sync while a KPI dashboard displays trends so you can adjust allocations on-the-fly. Eliminate paper timesheets, monitor driver and fleet performance, fully automate delivery statusing, capture electronic logs and vehicle inspections, manage 3rd party haulers, and more.

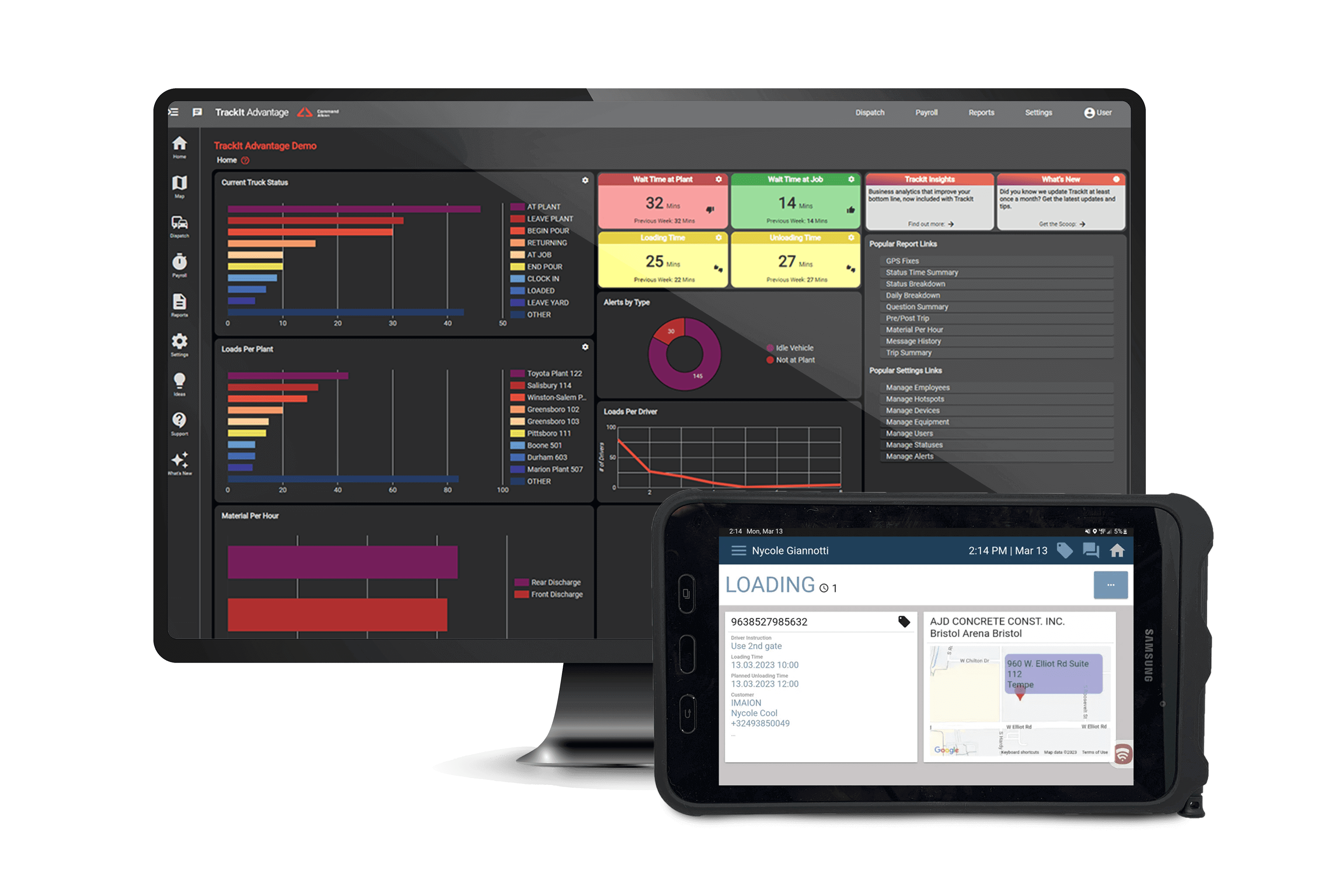

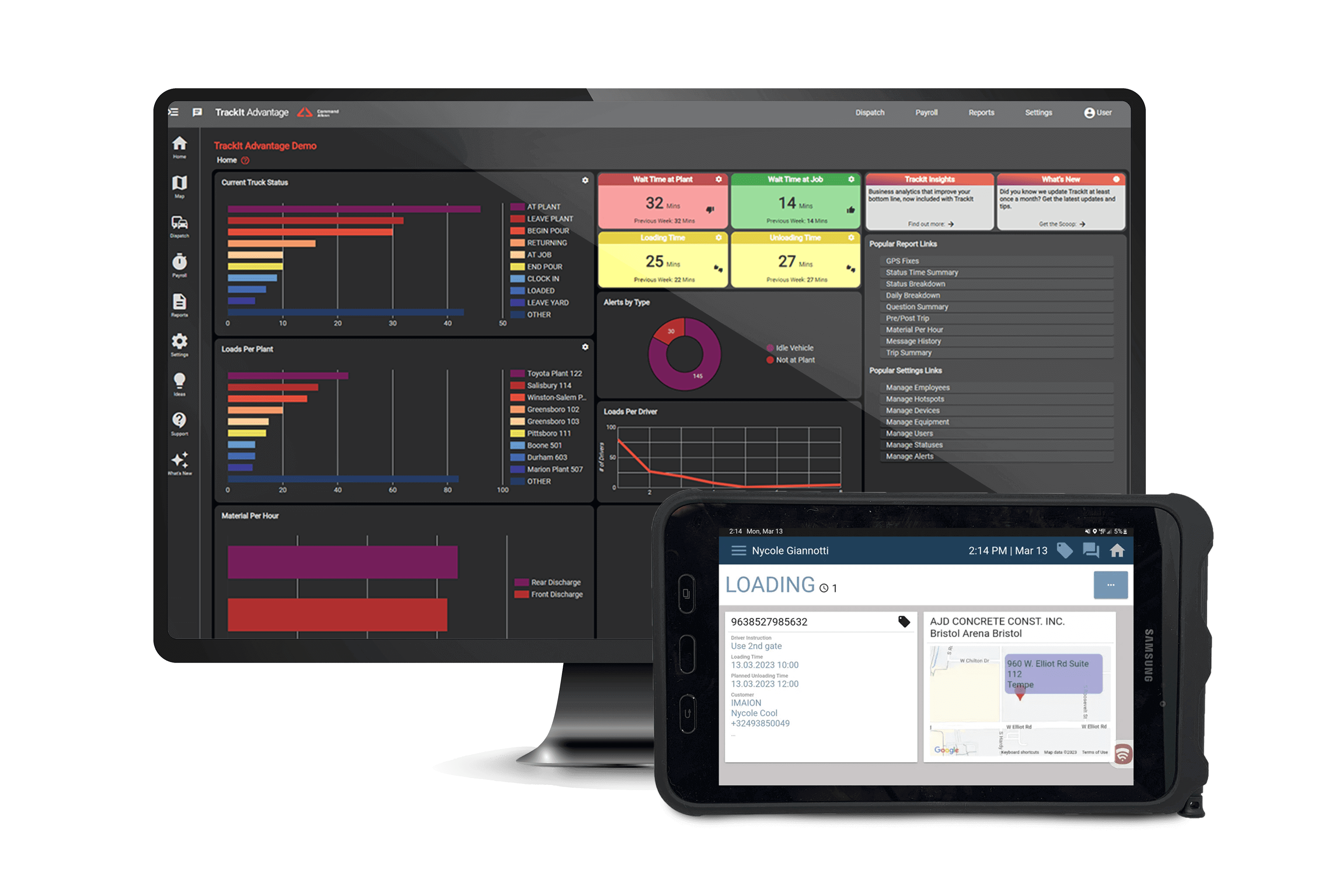

Cloud-Connected Mobility

TrackIt delivers mobile user experiences that are as flexible as they are fast, thanks to operating in the cloud. Drivers and Dispatchers stay connected and productive while the technology consistently captures statusing of ready mix and bulk delivery cycles.

FMSCA Compliance Support

Ensure compliance with FMSCA’s regulatory standards using TrackIt’s electronic driver logs. Includes a smart, accessible way to capture pre- and post-trip inspection reports designed to help you keep vehicles as productive as possible.

“TrackIt gives us the necessary tools to plan our day ahead instead of flying by the seat of our pants. It more than paid for itself within the first year of use.”

– Operations Manager, Osco Concrete

Automated Delivery Details

Fully automate your ready mix delivery cycle to capture begin pour, end of pour, loading, loaded, and wash statuses. Include a water added meter to capture accurate water added data to fully understand the quality perspective of each and every load.

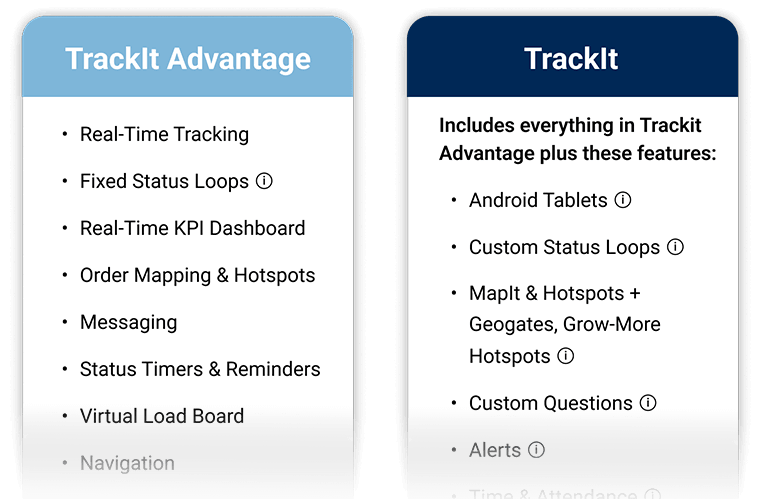

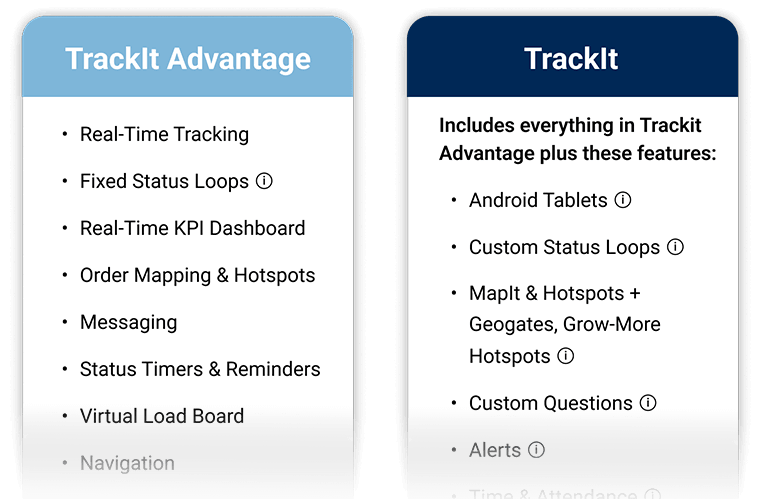

Looking for something lighter? Try TrackIt Advantage.

Tracklt Advantage is a light version of Tracklt for those that don’t need the full Tracklt package.

Made to Fit Your Needs

Compare full TrackIt to the more streamlined TrackIt Advantage.

Made to Fit Your Needs

Compare full TrackIt to the more streamlined TrackIt Advantage.

Extend Your Value

Have greater control over daily schedules, delivery planning, performance, and efficiency

Customers request, view, and monitor their orders 24 hours a day

Minimize manual testing and deliver materials in spec and with confidence

Request a Demo