load assurance

Time Saved. Quality Assured.

Eliminate Gaps in Communications

Streamline and Automate Your Manual Processes

Make More Accurate Decisions, Faster

WATCH NOW

Capture Visibility

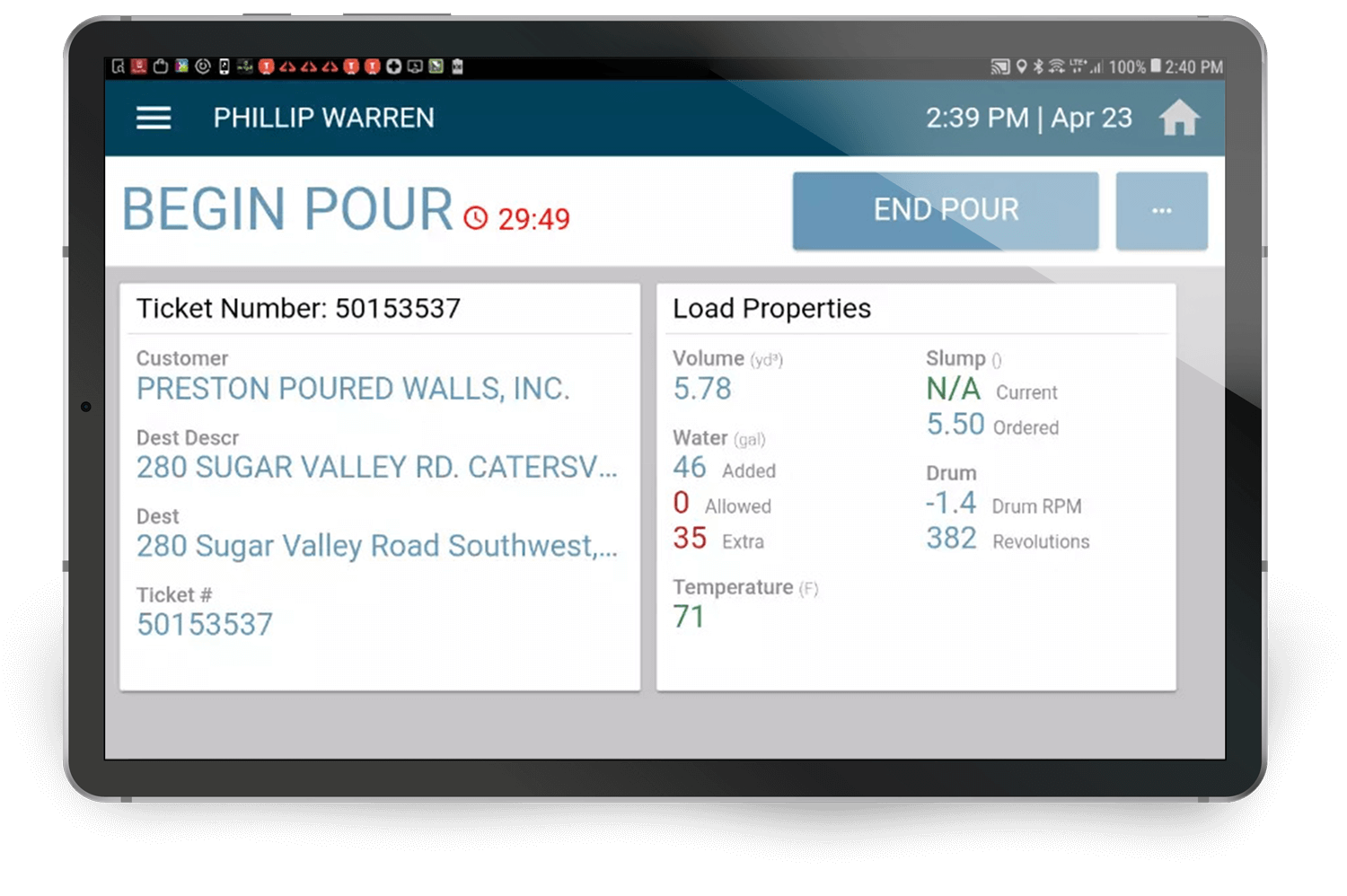

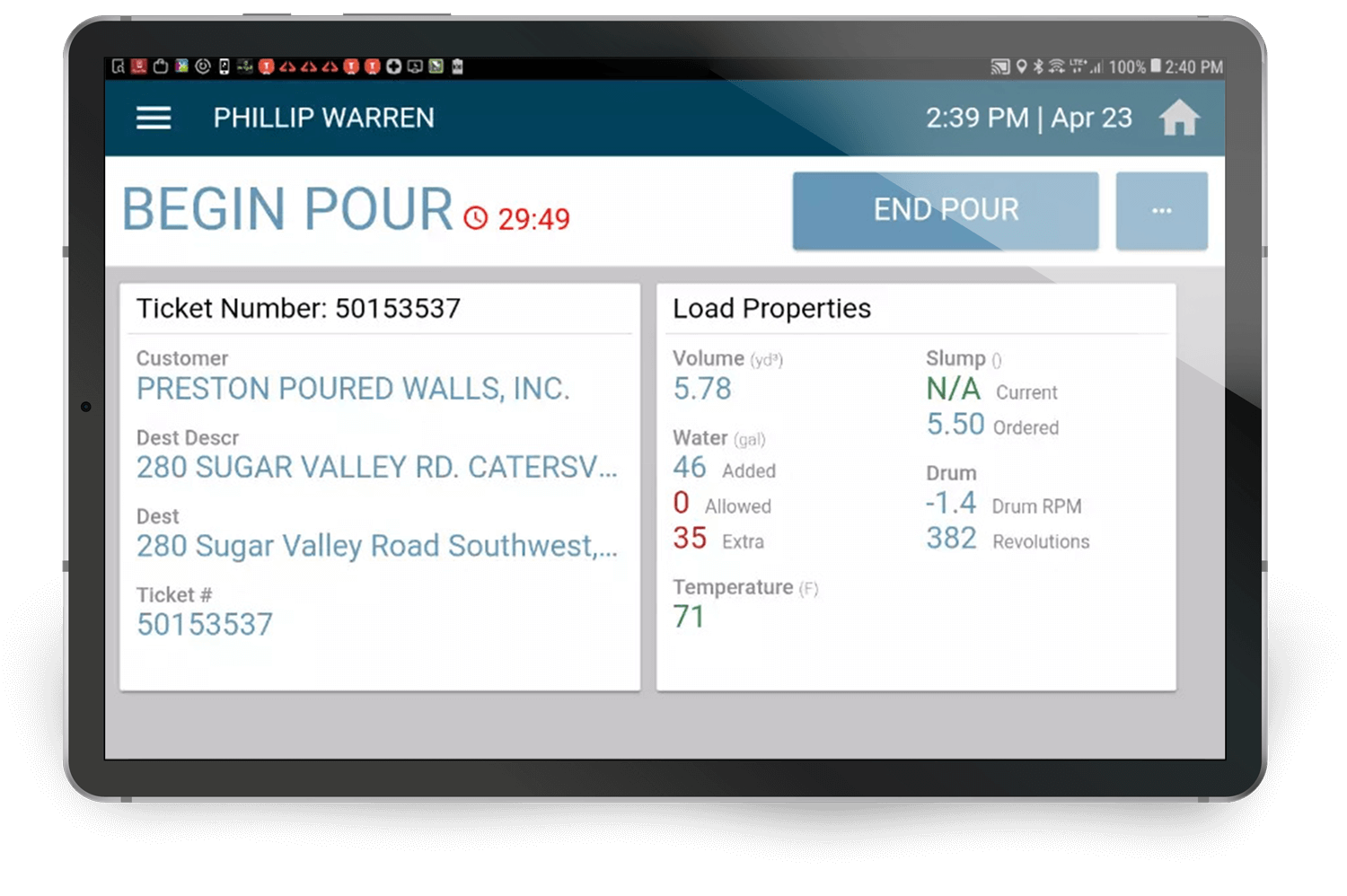

Into exactly what’s going on inside the drum of your ready mix truck. Be in the know all the way to the jobsite on Slump, Temperature, W/C Ratio, Water Added, Drum Speed, and Volume.

REAL-TIME & HISTORICAL DATA FOR READY MIX

Fresh insights into your fresh concrete helps you make adjustments to your next production cycle at the source. Let the data from each delivery improve the next load before it leaves the plant. And capture historical data for use by QC in optimizing mix designs and dispute resolution.

MINIMAL HARDWARE + EASY INSTALL

Give your fleet manager a break. With very minimal hardware, installation time is minimal and maintaining a fleet of hardware is simplistic.

“With Load Assurance, I can watch a load and monitor slump, temperature, and water-added during the entire lifecycle of the product being on our trucks from 100+ miles away, and know almost exactly, if not more than I would know if I was standing beside the truck without this technology.”

– Austin Davis, Wayne Davis Concrete

Save Time and Money

$240k

Driving Time Saved Annually

50

For a Fleet of 50

Extend Your Value

Drive decisions with critical data from anywhere with cloud-based dispatching

Delivering transparency into order information to Customers from a simple mobile application

Request a Demo